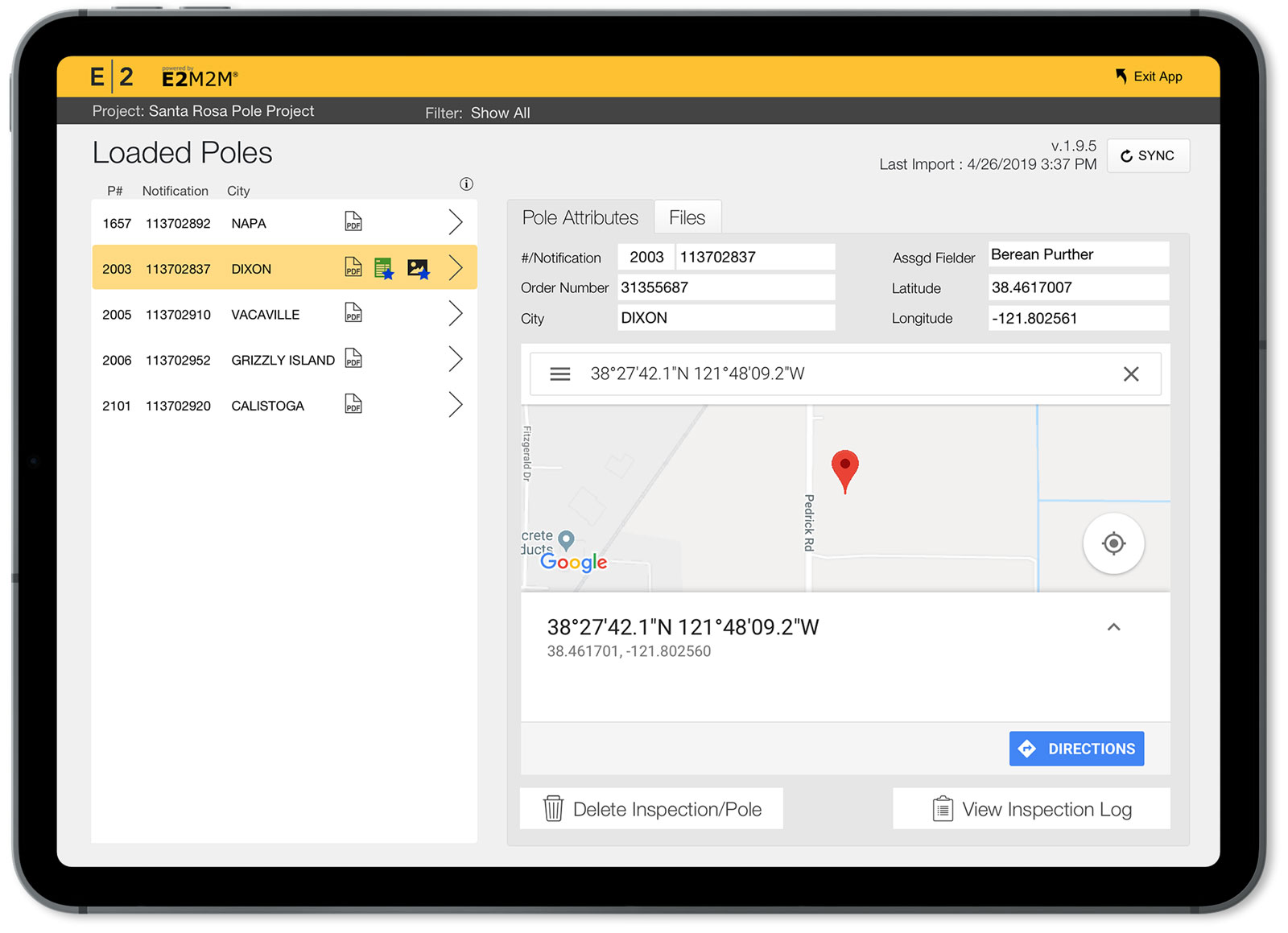

E2M2M® Construction Inspection Modules

A fully customizable application facilitating traceable, verifiable and complete data collection

STREAMLINE FIELD DATA COLLECTION FOR PIPELINE INSPECTION

E2M2M® Construction Inspection Modules are a compilation of web- and cloud-based applications used by both office and field personnel to track project progress daily and reduce lag time for critical decisions normally associated with construction and inspection. This is accomplished by entering as much controlled information applicable to the operator’s specific gas standards, as well as State and Federal codes.

The modules automate the generation of PDF forms for internal and external compliance purposes preventing end-users from altering the layout of a client’s documents. Data flows both ways within the application workflow: project information, documentation, drawings, and standards are pushed to field inspectors who are documenting construction activities, providing real-time information back to office personnel and decision-makers. The system allows a project controls manager to fully customize the chain-of-command for documentation approval and to receive data from the field as generated. Inspection forms and user-interface can be customized to operator-specific requirements.

CONSTRUCTION INSPECTION MODULES

PROJECT SHELL

Each project is created here, with milestones entered into a project calendar. Team members can be added for email notifications and assigning tasks. Level of approval may be used per a project’s DOA.

COATING MODULE

Allows the inspector to select joints of pipe, specific welds, or components, such as valves or fittings. All of these selections come from the pipe tally, bringing all critical data over to the coating report without error or double entry from the inspector. The system can detect calibration dates approaching expiration and alert the inspector proactively.

FIELD DOCUMENTS

The system has document repositories at both project-level and company-level. At the company level, the inspector can search and access critical oil/gas standards specific to the client’s operation. This allows for quick and informed judgments in the field as to expectations. The project-level documents allow for the storage of documents specific to a given project. This allows for easy reproduction, if necessary, creating a virtual job book.

PIPE TALLY MATERIAL TRACKING

MTR data can be entered or imported with critical information (heat number, grade, wall thickness, pipe size) protected from modification and reused where applicable. This greatly reduces error, allowing for traceability and closeout to be expedited while upholding data integrity. This later assists with quantifying excess material for salvage or disposal.

WELDING MODULE

Accounts for firing-line operations, tracking multiple inspectors’ input to a single weld and can easily be used for yard welding, with one inspector entering data efficiently for multiple welds. Prevents weld identifiers from being duplicated on a project. Assists with correct WPS selections. The welding component allows for tracking of NDE Type performed & radiography indications/defects found, while maintaining welder rejection rates.